|

|

|

|

|

Various Photoluminescent Products |

|

|

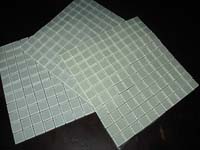

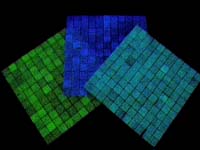

Photoluminescent glow glass mosaic

Photoluminescent

crystal glass mosaic, without power overnight light, energy saving! Under

natural light seemingly ordinary mosaic, there are yellow-green, white and other

colors, dark yellow impose green, blue-green, sky blue and other colors, after a

sufficient absorption can glow in the dark at the time of 8-12 hours a month,

saving environmental protection to achieve low-light illumination. Size: 25mm *

25mm * 4mm, 11.3 units per square meter, each size is 297mm * 297mm. Transparent

light, add extraordinary night of mystery and romance for unlimited building

itself!

We

can also be customized in different sizes! There are also a variety of styles,

you are welcome to contact us! Scope: swimming pool, hotel lobbies,

channels, entertainment, bars, shopping malls, kitchen, bathroom, backdrop,

skirting, senior toilets.

Features:

*

Environmental protection, no radiation * Construction convenient * Pastel colors

*

Does not change color * Easy to clean *

Insulation for walls with moisturizing effect.

|

|

|

|

|

|

|

|

|

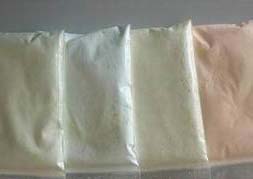

Photoluminescent Paint

After special surface

treatment, the photoluminescent pigment can be incorporated into paints as a

kind of color additive to produce diverse types of photoluminescent paint, For

example: water-based paint, sand-textured paint, road marking paints, floor

paint and metal paint.

Photoluminescent water-based acrylic paint is a novel environmentally friendly

paint. Adopting water as the medium, with the advantages of non-toxicity,

hard-flammability, good adhesion, good weather-resistance, outstanding luminous

effect, It can be used on the surface of such materials as cement, wood, metal

and plastic etc. It is mainly applied to the surface of machine tools, machinery

equipments, auto, construction machineries by means of spraying or brushing. The

luminance color include Yellow-Green , Blue-Green ,sky blue, red .

|

|

|

|

|

|

|

|

|

Photoluminescent Fabric and Thread, Strip

Luminous toys fabric, luminous shoes, hats luminous fabric, luminous yarn, luminous cord, luminous table cloth, luminous PU leather, luminous plush fabric, luminous nylon fabric, luminous elastic cloth is a new product. Whether and other silk, cotton or synthetic textile fabrics, after the adoption of high-tech special treatment, can achieve self-luminous function, showing amazing visual effects. After washing, ironing, cutting, still maintain their luminescent properties and environmentally friendly non-toxic products are widely exported to Europe and East Asia and other countries and regions. Suitable for a variety of high-end functional fashion, pajamas, ties, clothing, evening dress, footwear, toys, curtains, wall covering, bedding, handbags, furniture, sofas, large entertainment nightclub costumes clothing and other senior traffic police at night clothes and so on.

|

|

|

|

|

|

|

|

|

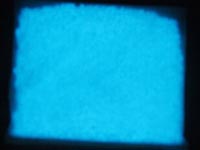

UV Fluorescent Pigments

Other name: anti counterfeit

fluorescent pigment, invisible ultraviolet light excite powder, security

pigment

The UV fluorescent pigment usually use for make anti counterfeit printing ink, then use for security purpose. Also can be use for drawing for entertainment place , the design can show under the UV light.

The UV fluorescent pigment include two kinds, one is organic UV fluorescent pigment, another one is inorganic UV fluorescent pigment.

The UV fluorescent pigment also include long wave type (excitated by 365nm wavelength ) and short wave type (excitated by 254nm wavelength ).

For use in anti counterfeit purpose, long wave security technology is widely use for bill , currency anti counterfeit , The differentiate instrument is popularization. In marketplace or bank often use currency detector to identify . The short wave security technology need use specially instrument to identify, so have more strong anti counterfeit performance.

|

|

|

|

|

|

|

|

|

Photoluminescent Plastic Master Batch

Luminous plastic masterbatch is a kind of self-luminous function plastic masterbatch, the use of

long afterglow photoluminescent pigment, after the processing of. It can be used directly or mixed with other similar plastics, made

to various plastic products.

Features: 1: plastic varieties (ABS, PP, PE, PC, etc.) 2: containing

glow powders proper proportion, the degradation process can use as needed. 3:

Photoluminescent pigments distribution well-proportioned, use of the process is not easy to precipitate. 4:

Extrusion or injection molding process to avoid the occurrence of high temperature and heavy metal exposure.

Usage: For example: PP polypropylene luminous masterbatch for use Masterbatch composition:

1. Masterbatch composition: the high brightness and luminous and PP resins with a variety of additives made

by granulation. 2. Features: glow in dark powders content to 10-30%: The advantage is so luminous in the products distributed evenly, and easy to use, which contain a variety of additives help to improve aging products, but also can enhance toughness.

3. Scope: can be used with many types of PP resin ,mix can also be good compatibility with PP resin mixed with other resins, by injection molding, extrusion, blow molding

craft to make various glow in dark plastic products.

Mixed according to the following formula: (PP masterbatch) :( PP resin) = 1: (M / N-1) M is the percentage of masterbatch

photoluminescent pigments. N is the percentage needed to achieve the luminous powder.

For example: masterbatch glow powders content is 30%, the required content is 10%, do the following calculation: (PP masterbatch): (PP resin) = 1: (0.3 / 0.1)

.

|

|

|

|

|

|

|

|

|

Photoluminescent Mimic Marble Tile

Made from resin materials. Can cut into size according

to customer's requests.

|

|

Photoluminescent Ceramic Glaze

Use for make interior and floor tiles. Mainly include

yellow green, blue green, sky blue glow colors.

|

|

|

|

|

|

|

|

|

Reference Knowledge

|

UV-fluorescent pigments, fluorescent security inks, how to

use them and technical informations:

Using fluorescent ink types for packaging security is good or bad, it is very important that if you choose not accurate or poor, it may lead to ineffective or do not achieve the security of any of the security requirements, such as color-theory based on the color of light and a light absorption principle, the color of the long wavelength absorption of short wavelength light. The following analysis of fluorescent ink in the actual product structure in specific circumstances.

If we printed colorless fluorescent blue ink on the full version of the golden coating, then, first of fluorescent blue ink layer under the UV lamp shines, showing blue (B) colored light, and then with the golden undercoat end (Y) Shade mixed, from shade additive color theory analysis, yellow and blue light mixed, showing a white light, yellow light and blue light that is mutually complementary color, that poor security effect or in some cases simply can not to any security role. From the bottom of the absorption of light theory, this is because the spectrum of life in the long-wave yellow light blue short wavelength light absorbing portion to see the blueprint should be rendered fluorescent colors. The red fluorescence, etc. in the published works well, the effect in the standard light irradiation.

Thus, we can arrive at a junction perish, the choice of fluorescent security inks - scheduled to be careful, general printing system has produced its complement exist or shade of ink than the color ink selected fluorescent inks long waves exist, After this kind of fluorescent ink is best not to use or reach a certain security effectiveness. So in the pharmaceutical packaging industry uses fluorescent security ink production process, the printing system for printing a variety of different fluorescent ink primer material selection is particularly important. Besides the use of fluorescent ink for the printing process requirements more stringent, because of the special nature of its ink system, generally in the course we should pay attention to consider some of the following factors:

① As the drugs commonly used in packaging and printing processes are intaglio, gravure therefore very important for the choice of solvent. The solvent is an important component of the gravure ink, has solubility and volatility, the evaporation rate is to determine the type of volatile and printing quality of the ink drying speed is an important factor. Slow evaporation of the solvent, for printing an image reproducibility is better, but if the evaporation rate is too slow, the print has not been completely volatile, prone to the fluorescent ink adhesion, resulting in blurred images counterfeiting, layout plays dirty, security effectiveness and impact of the overall appearance of the product; Conversely, if the ink solvent evaporation during the printing process too fast, it will produce ink whitish, sticky rolls and other phenomena, and lurks hidden faults sticky ink back, causing the back of the packaging material from dirty, ultraviolet light shines bright piebald F can clearly see the heavy, so that consumers have unsanitary intuition, severe cases may affect the coating and laminating processes under the channel.

Due to various manufacturers of printing equipment, the operating environment is different, for example, the speed of printing, drying system structure, characteristic printing materials, indoor temperature and humidity must be considered, so the printing process solvent under Arts Use comprehensive consideration of all the factors. Resin binders are usually relatively dissolution parameters, combined with the above requirements, the choice of two or three different boiling solvents used in conjunction with, can achieve the desired effect of complete security pattern.

② fluorescent ink in security printing layout - as the proportion of very small, small fluorescent inks can produce a large number of counterfeit products, so in the production of fluorescent ink products, the task should be in accordance with the order book: reasonably indicate the number of calculate the amount of ink, for a one-time run out, not left too much unnecessary waste. General fluorescent ink products can not be long-term repeated use, one easily from dirty, not clean unnecessary layout problem, the second is after a long fluorescent pigment ink system solvent rinse dilute, the fluorescent anti-counterfeit effect is greatly reduced, even in the UV lamp irradiation pattern or text also appears bleak, not achieve the desired effect of security.

Fluorescent anti-counterfeiting materials, UV phosphors, phosphor violet display

This series of special phosphor under visible light, showing white or nearly transparent color, light sources at different wavelengths (254nm, 365 nm, 850 nm) show one or more fluorescent colors, including organic, inorganic, twilight and other special effects , colorful and bright.

First: the product color

This series of products there are a wide variety of color white, blue, red, yellow, green, purple, orange, pink, various colors, endless variations.

Second: product characteristics:

A. Inorganic phosphor

1 fluorescent bright color, good hiding power (opacity can be added free agent).

2 fine spherical particles, easily dispersed, 98% of the diameter of about 1-10u.

3 good heat resistance: maximum temperature of 600 ° C, suitable for high-temperature processing of various treatments.

4 good solvent resistance, acid, alkali, high stability.

5 no color shift (MIGRATION), does not pollute.

6 non-toxic, will not overflow Formalin (FORMALDEHYDE) when heated, can be used on toys

And coloring food containers.

7-color body does not overflow, when the injection molding machine for mold, you can save cleaning procedures.

B. organic phosphor

1 fluorescent bright color, does not have a hiding power, light penetration rate of over 90%.

2 good solubility, dissolution Jieke various oily solvent, but with different solubility, when used in accordance with the need not

Be selected with the demand.

3 belong to dye series, should pay attention to the color shift problem.

4 due to poor weather resistance, need to add the use of other stabilizers.

5 Heat resistance: maximum temperature of 200 ° C, 200 ° C or less suitable for high-temperature processing.

Third: the product uses

1 can be used in a variety of plastics such as PE, PS, PP, ABS, acrylic, urea, melamine, polyester

The fluorescent colored resin.

2 Ink: Due to a good solvent resistance and no color shift of the printing of the finished product will not be contaminated.

3 Paint: resistance to rotation three times stronger than other brands, lasting bright fluorescence can be used for the benefit and safety warnings printed advertising.

Organic and inorganic UV fluorescent, red, yellow, purple, white, blue, yellow and green light phosphor

The company is specialized in anti-counterfeiting security ink luminous powder synthesis and production of high-tech enterprises. Has specialized synthetic organic chemistry professor, led the research team.

There are: 254nm, 365nm, infrared upconversion (infrared excitation) and other series of colored invisible luminous powder.

A, 365nm excitation longwave ultraviolet light-emitting organic powder are:

1, colorless fluorescent Pink: organic complexes, high luminous efficiency, luminous efficiency relative to the general market selling organic UV emission Pink at least 20% higher, more color in bright red under ultraviolet light, and the high degree of resistance to UV aging..

2, colorless fluorescent yellow-green powder: organic heterocyclic compounds, the luminescence excited by ultraviolet light emitting powder bright yellow green.

3, colorless fluorescent green grass powder: organic heterocyclic compounds, the UV luminescence excited by ultraviolet light emitting bright grass-green fluorescence, has been widely used instruments, securities and other security.

4, colorless fluorescent blue powder: organic heterocyclic compounds, high luminous intensity.

B, 254nm shortwave ultraviolet excitation of organic light-emitting powder are:

1. A colorless fluorescent green: organic complexes, high luminous intensity, luminous powder composites with 365nm can achieve the dual security effectiveness.

2, colorless fluorescent red: organic complexes, luminous efficiency is higher than the general market sales of similar powders.

|

|

|

|

Photoluminescent

Pigment P.L.

Pigment Specification

|

|