|

Phosphorescent Emergency

The innovative glow-in-the-dark pigment

as a substitute for radioactive self-luminous pigment for watches and clocks is

rapidly becoming a useful material for safety systems in commercial aircraft.

"Go!! Go!!" An instructor

shouted the order to evacuate the dark cabin. Passengers left their seats and

groped for a way to escape. They stooped to avoid the smoke, and saw a line

glowing brightly on the floor. It was the phosphorescent evacuation path

marking! Passengers followed the glowing line to the emergency exit. In this

way, 19 people ranging in age from 19 to 51, including two passengers who had

never flown before, were able to escape from the dark cabin.

This is a description of a human

observation test conducted by FAA (Federal Aviation Administration) using the

CAMI (Civil Aero-Medical Institute) Air Craft Cabin Evacuation Facility to

confirm the visibility of phosphorescent floor path evacuation markings in

aircraft. Representatives from the aviation authorities of Britain, France and

Germany also attended the test.

A hypothetical emergency scenario was

used for the test. A nighttime flight of intermediate duration resulted in a

lights-out condition of 150 minutes before an emergency landing was made in

complete darkness. Inch-wide strips made of conventional ZnS based

phosphorescent pigment and strontium aluminate based new pigment were fitted

along each side of the aisle. 150 minutes before the test started, the strips

were exposed to a 25lux light for 30 minutes.

According to the test results summarized

in the FAA report (Feb. 1998, DOT/FAA/AM-98/2)PDF file, strips made of

conventional pigment were not visible enough but the strips were easily

recognized. The FAA report concluded that the strontium aluminate

photo-luminescent materials provide better behavioral cues to guide the

individual human observer movements along the aisle toward the exit.

Table: Afterglow luminance of

phosphorescent floor proximity markings (mcd/m2)

Type of photo-luminescent material

Time (Min.)

0

30 60

90 120

150

YG-200

13.7 3.8

3.0 2.7

2.5 2.4

Conventional material (ZnS)

14.7 1.6

1.1 0.9

0.8 0.7

Excited with 25lux incandescent lamp for

30 minutes

Measuring conditions; measuring angle -

33 degrees, at a distance of 206cm

Federal regulation 14 CFR 25.812*1

requires that all passenger aircraft must have Floor Proximity Emergency Escape

Path Markings. The conventional passenger cabin floor path strips are made with

miniature incandescent bulbs or EL panels, which are lit in cases of emergency.

The conventional systems sometimes do not work properly because of battery or

wiring failures, burned-out light bulbs, or physical disruption caused by

vibration, passenger traffic, galley cart strikes, or hull breakage in

accidents. In addition to costing money, any repair of these systems would

undoubtedly be a cause of delay for some flights.

In the past, Photo-luminescent materials

had been tried as a solution to this problem but the available phosphorescent

materials did not conform to the brightness and afterglow duration requirements.

That is glows ten times brighter and ten times longer than conventional

phosphorescent pigment, has solved this problem.

Lufthanza FloorPath

Normal lighting conditions

Dark

Photo: Emergency Floor Path markings in

passenger cabin

Similar visibility tests were conducted

in Europe also using Airbus A-340-300, with Gumlu proving its superiority again.

Lufthansa German Airlines was the first company to adapt its to actual emergency

floor path markings. The floor path markings were installed in mid-range

passenger aircraft for Lufthansa commercial flights in Europe.

It is said that there currently are

about 10,000 passenger aircraft in the world, about one tenth of which have

already been equipped with Emergency Floor Proximity markings. Recently, the

materials itself has also been improved. New grades can be excited with lower

intensity light while emitting a more intense afterglow. It may not be very long

before Gluma floor path markings are also installed in long-range passenger

aircraft. While it is our sincere hope that such a situation never arises, we

are pleased to protect passenger safety.

Passenger aircraft shall have Floor

Proximity Emergency Escape Path Marking Systems (FPEEPMS), which will provide

visual guidance for emergency evacuation of passenger cabins when all sources of

cabin lighting obscured by smoke.

FPEEPMS will enable each passenger to

visually identify the emergency escape along the cabin aisle floor after leaving

the cabin seat, and to readily identify each exit from the emergency escape path

by reference only to marking and visual features not more than four feet above

the cabin floor when all sources of illumination more than four feet above the

aisle floor are totally obscured and when it is dark.

Transport category aircraft are required

by 14 CFR 25.812 to have emergency lighting systems, including floor proximity

marking systems. Typical floor proximity marking systems installed on transport

category aircraft have been primarily comprised of incandescent luminaries

spaced at intervals on the floor, or mounted on the seat assemblies, along the

aisle. The requirement for electricity to power these systems has made them

vulnerable to a variety of problems, including battery and wiring failures,

burned-out light bulbs, and physical disruption cause by vibration, passenger

traffic, galley cart strikes, and hull breakage in accidents. Attempts to

overcome these problems have led to the proposal that non-electric

photo-luminescent materials be used in the construction of floor proximity

marking systems. To assess the viability of this proposal, performance

demonstrations of systems made with such materials were conducted. It was found

that STRONTIUM ALUMINATE photo-luminescent marking systems can be effective in

providing the guidance for egress that floor proximity marking systems are

intended to achieve; in contrast, ZINC SULFIDE materials were found to be

ineffective.

Phosphorescent Evacuation

On March 8, 2000, a subway accident took place in Tokyo. Trains

derailed, six people were killed and sixty injured. If this accident had taken

place in a tunnel instead of an open area, these numbers would certainly have

been much higher. It is easy to imagine the panic caused if the accident victims

were unable to determine the correct direction to evacuate the scene. In such

situations, it would be very helpful if Glow-in-the-dark signs were installed in

tunnels to show passengers the direction and distance to the nearest station.

This phosphorescent Evacuation Route Guiding Sign

directs potential accident victims to the nearest station.

Recently such phosphorescent signs were installed in a tunnel on the

Nanboku line subway in Tokyo. The 30 x 60cm signs are made using a special grade

phosphorescent pigment, which does not need any exclusive lighting apparatus for

excitation. The light leaking from the windows of the passing trains is enough

to activate these signs. After the successful field test on this subway line, it

is expected that these signs will also be installed in other lines currently

under construction.

Glow-in-the-dark signs are helpful not only for subways but also for

other underground areas such as shopping malls, underground passages, and

basements in the event of a blackout. Therefore the installation of

Glow-in-the-dark signs is regulated by fire safety law.

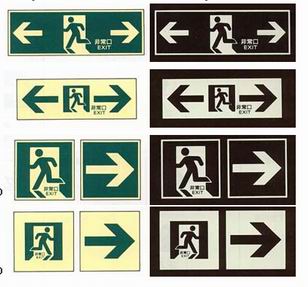

The Fire Fighting Agency's 1988 guidelines regarding "Exit signs

and Evacuation route guiding signs" specified that the:

"Installation of emergency signs made of phosphorescent materials

is recommended since they emit light even in the dark. Such signs should conform

to JIS Z 9100 (Phosphorescent signs) and JIS Z 9115 (Self-luminous signs)"

This JIS standard for phosphorescent signs was recently revised because

of the drastic increase in the afterglow intensities obtainable when using

phosphorescent pigments, and the new Phosphorescent Safety Signs has replaced

the old specifications.

Table: Afterglow luminance of phosphorescent floor proximity markings

(mcd/m2)

Type of photo-luminescent material

Time (Min.)

0 30 60 90

120 150

AT20 13.7 3.8

3.0 2.7

2.5 2.4

ZnS 14.7

1.6 1.1

0.9 0.8

0.7

Excited with 25lux incandescent lamp for 30 minutes

Measuring conditions; measuring angle - 33 degrees, at a distance of

206cm

As shown in the above table, the new standard afterglow values are five

to six times higher.

European safety signs

Photo; Examples of European safety signs

As far as international standards are concerned, ISO/FDIS 15370

1(Evacuation route guiding signs on passenger ships) regulates that the width of

the evacuation pass markings can be reduced down to 25mm from the conventional

75mm (using ZnS based pigment). ISO/CD 17398 2(Safety signs) is currently under

discussion for a revision taking this new JIS as a reference.

Phosphorescent material usage in European countries for fire safety

signage has the highest utilization in the world. Approximately 100 metric tons

per year of Phosphorescent pigment for sheet products is used. Many European

sheet manufacturers have already begun to shift their production to high

performance.

Emission spectrum of halogen lamp

Do highway tunnels not require phosphorescent signs? Under normal

conditions, light is not of concern because of tunnel electrical lighting and

headlights of the vehicles using it. However, should an accident or an

electrical malfunction occur, tunnel lighting could become a problem.

Phosphorescent materials that are effectively excited by headlights would be

very helpful for use in highway tunnels. Unfortunately, modern headlights are

equipped with halogen lamps. As shown in the above figure, their emission

spectrum is not rich in the UV that is the most effective for the excitation. In

order to solve this problem, LUMINTEC. were successful in developing a new

version which can be excited by halogen lamps. The phosphorescent features of

this new grade are shown in the table below.

Table; Comparison of new type with regular type.

After: 1min

5min 10min

20min 30min

Regular 100

100 100

100 100

New type 336

235 214

180 180

Excitation conditions: 600 lux (two 55watt halogen type headlights at

5meters for 30seconds)

The development of this new type has enabled LUMINTEC. to produce phosphorescent signs not only for highway tunnels but also for roads where ambient lighting is not present. This new version will be useful for accident prevention on rural roads or similar places where only headlights are available for excitation of the safety signage.

|